Our new client is a global leader in manufacturing innovative powertrain solutions. It supplies high quality OEM parts to the automotive industry. The company has production facilities in North America, Europe and Asia.

What did the client need?

The client was looking for a washing device that could be integrated with the production process of two half-shaft projects. After the mechanical treatment of steel components, it was necessary to remove contaminants such as metallic and non-metallic particles. Key requirements included automation of parts loading and unloading, as well as achieving a washing process efficiency of 25 seconds per part.

Solution implemented for the Client

We offered a device from the NOYEN Expert C series – a carousel washing machine in a compact size adapted to the layout of the production hall. The device has been installed at the final stage of two production lines and allows washing of various part references.

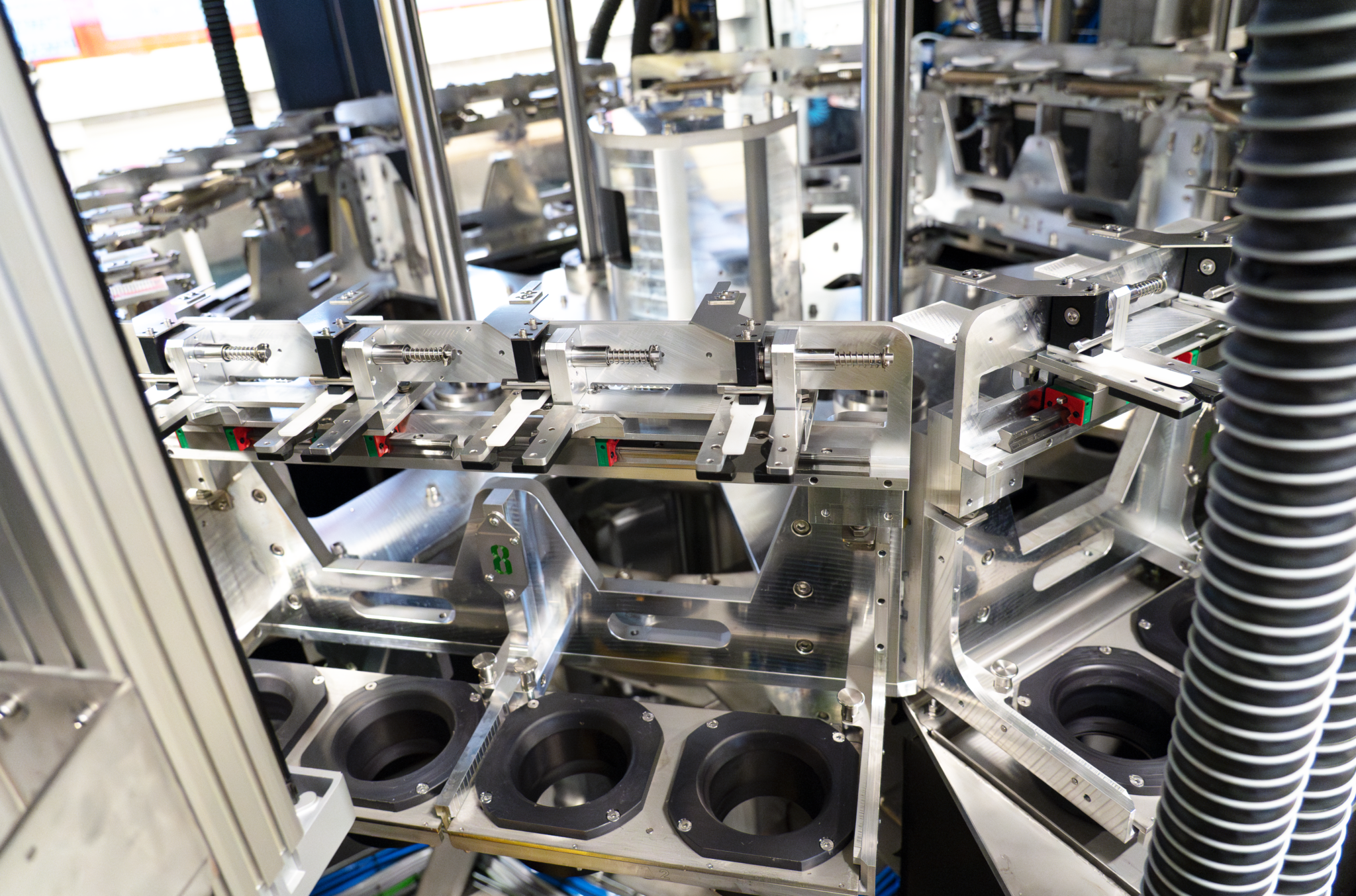

The cleaning machine has a process chamber equipped with two washing stations, two rinsing stations, a drying station and a station for assembling plastic covers. Parts are transported between stations by an automatic transfer system. The process is based on two washing technologies: spray and ultrasonic immersion. It is also supported by a double fine filtration system, which allows less frequent bath changes and ensures compliance with quality requirements.

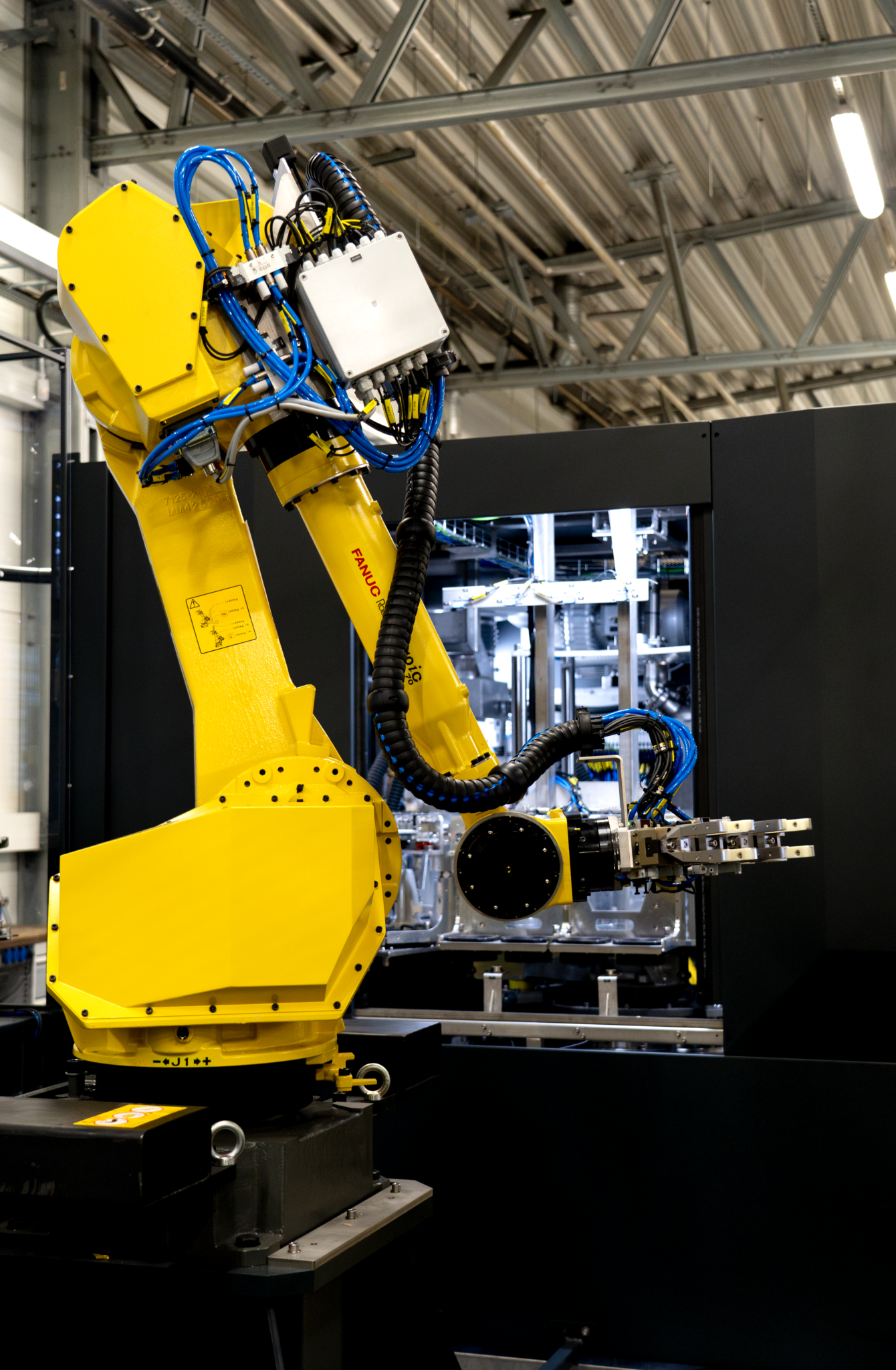

The device is equipped with automation with a buffer station. We have implemented two industrial robots into the process. The first one is used for automatic application the casings to the previously washed and thoroughly dried half-shaft surface. The second robot, responsible for picking the parts from the loading area, ensures high efficiency. The automation of the loading and unloading operations has improved the process and allowed us to achieve the performance requirements.

Dimensions of the cleaning machine (mm): approx. 2200 x 3750 x 2500

Loading capacity: 2 x 10 kg

Wash cycle time: approx. 25 seconds / part

As a result of the cleaning technology selection, we proposed our proprietary low-foam chemical NOYEN PAL+ for cleaning many types of metals, which is highly effective at low concentrations. Thanks to the special composition, the parts gained temporary corrosion protection after washing for the storage period.

What did the Client gain from cooperation with NOYEN?

- A washing device adapted to two production lines

- Possibility of easy and quick retooling

- Automation of loading and unloading operations

- Efficient cleaning process without the need for additional staff

- Full technological selection and support from NOYEN in the process

Nothing is impossible

It will be much easier if you tell us what is the matter. Save some time and sign up for a free consultation. Our expert will advise you free of charge.