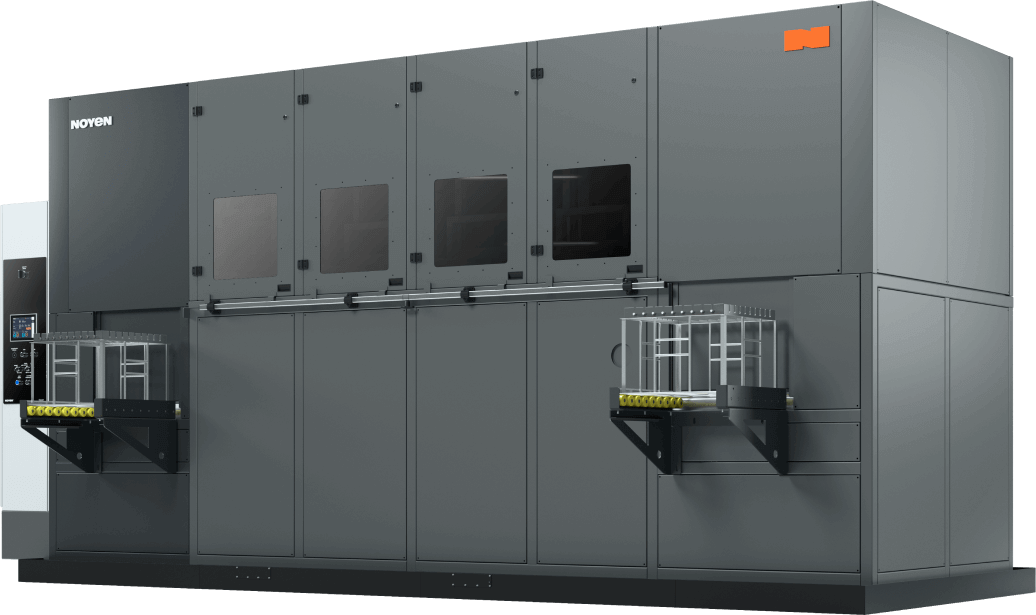

Ultra level industrial cleaning

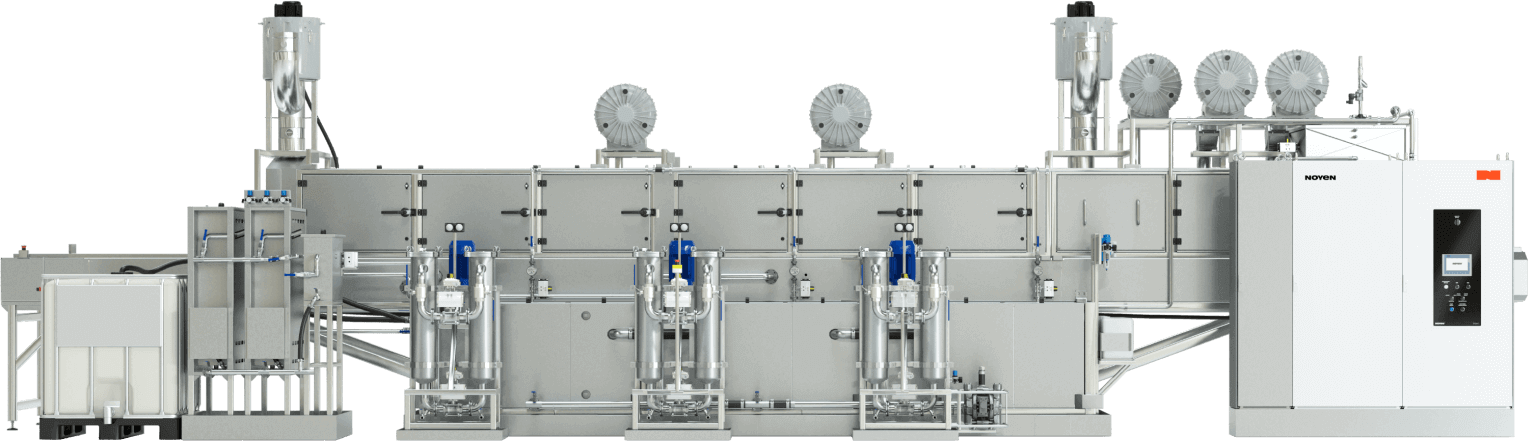

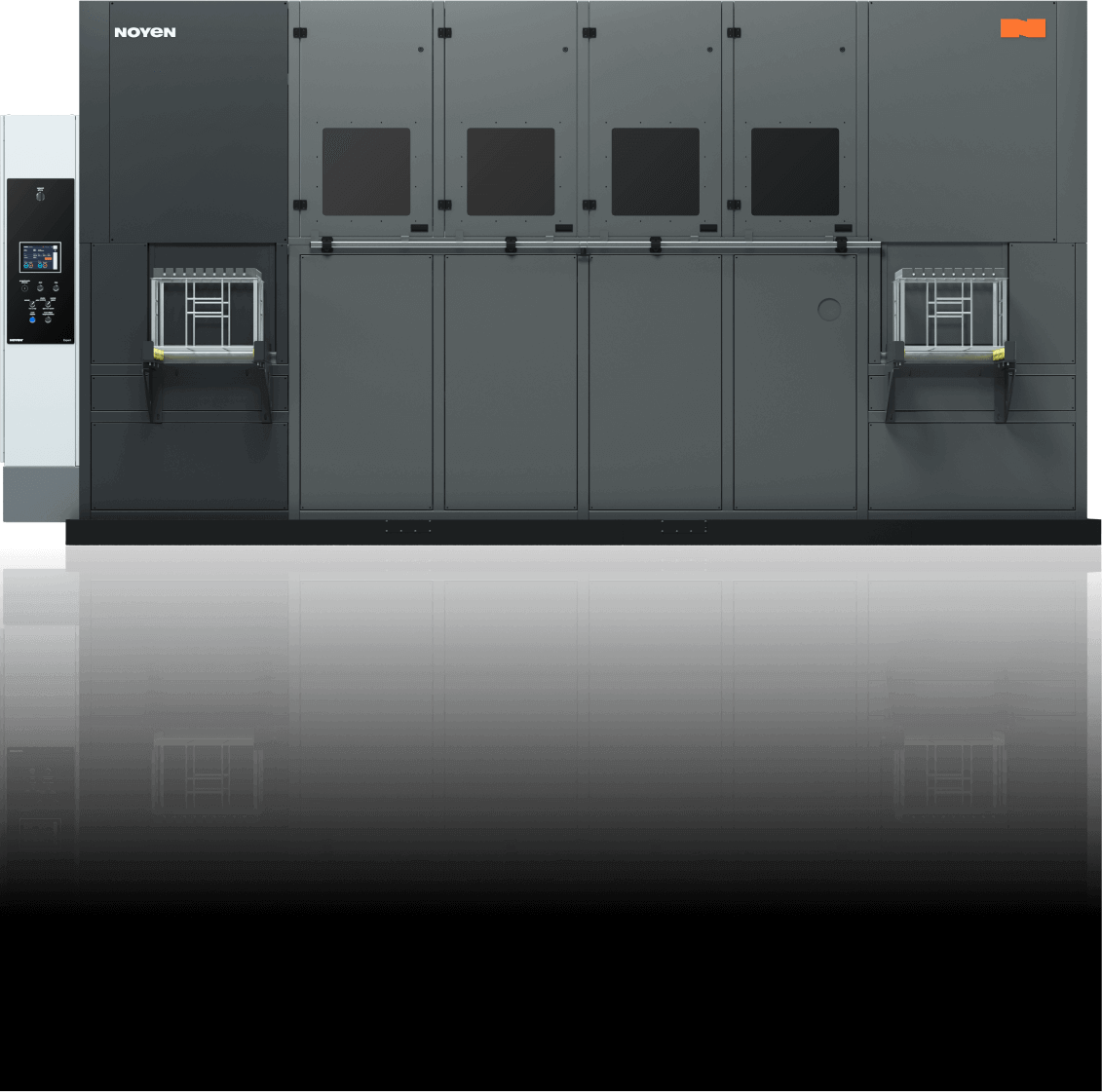

Separate chambers, parallel processes

Increase efficiency to the Ultra level by conducting many processes at the same time. Modular construction and internal part transport system save every second to effectively clean even the most delicate parts.

Discover

Ultra

- highest cleanliness norms

- traceability ready

- thorough cleaning of delicate parts

Perfectly fit the machine to your needs. Always. Its modular construction lets you conduct any number of processes at the same time. If you need, you can add new chambers or change the purpose of those you already have.

FIND OUT HOWThoroughly clean even the most delicate parts. The cleaning process is supported by component movement. This increases accuracy and speeds up the contaminant removal.

CHECK HOW IT’S POSSIBLEDedicated basket lifts make it easier to load and unload the machine, which makes work more efficient. You can raise it to the ultra level if you add a manipulator or a Robotics series machine.

DISCOVER NOYEN AUTOMATION

Ultra Clean

Gain highest cleaning quality thanks to multi-level filtration and bath replacement during the process. An oil separator continuously cleans the bath, which works in a closed circuit. This is responsible use of natural resources.

-

4 washing technologies ultrasonic, spray, immersion, flooding

-

3 cleaning support systems tilting, oscillation, 360° rotation

-

2 drying technologies hot-air drying, vacuum

Ultra is ready to be connected to the traceability system in your company. Traceability is part of Industry 4.0 which elevates production to a whole new level of quality. Are you ready for Ultra?

Technical data

| TECHNICAL DATA OF AN EXAMPLE CLEANING MACHINE ULTRA | |

| External size [length x width x height] | 11000 x 5300 x 3500 mm |

| Tank material | steel 1.4301 (304L) |

| Loading space | Basket 650 x 470 x 300 mm |

| Payload | 50 kg/basket |

| Processes | 2 x spray and ultrasonic washing, 2 x immersion rinsing, spray rinsing, convection drying, vaccum drying |

| Method of transport | Manipulator |

| Spray pressure | 5 bar |

| Ultrasound frequency | 1,5 kW/chamber |

| Tank capacity [liters] | 3 x 700, 2 x 350 |

| Heating | Electric |

| Heating-up time 10–60°C | 3 h |

| Thermal insulation | Armaflex |

| Total curb weight | ~13500 kg |

| Water treatment | Coalescent oil separator 200 l |

| Filtration | 2 x parallel bag filtration |

| Additional | Automatic water refilling system and chemical dosing system |

Nothing is impossible

It will be much easier if you tell us what is the matter. Save some time and sign up for a free consultation. Our expert will advise you free of charge.