Final cleaning for technical cleanliness of a rotor shaft

A global company producing components for electric car engines faced the challenge of manufacturing, and consequently industrial cleaning, of metal parts after machining. The parts were contaminated with oil, coolant from machine tools, metallic particles and abrasive particles from processes such as grinding.

What did the client require?

- Cleaning machines for the automated production line, with degreasing prior to induction hardening, and final cleaning for technical cleanliness requirements. The manufactured parts were to meet strict cleanliness standards.

- The parts were to be additionally protected with an anti-corrosion coating after the washing process, for further storage and subsequent assembly processes

- Design of compact equipment due to the limited space on the production floor

- The equipment was to be prepared to work with an operator and at the same time designed in such a way that, in the next stage of the investment, the client would be able to automate without any structural changes to the cleaning machine

What is more, the parts to be cleaned were only in the design approval phase, which required our Project Manager to be in constant contact with the client and make any changes to the design on the fly, adapting the machine to the changes made to the parts.

Solution implemented at the customer’s site

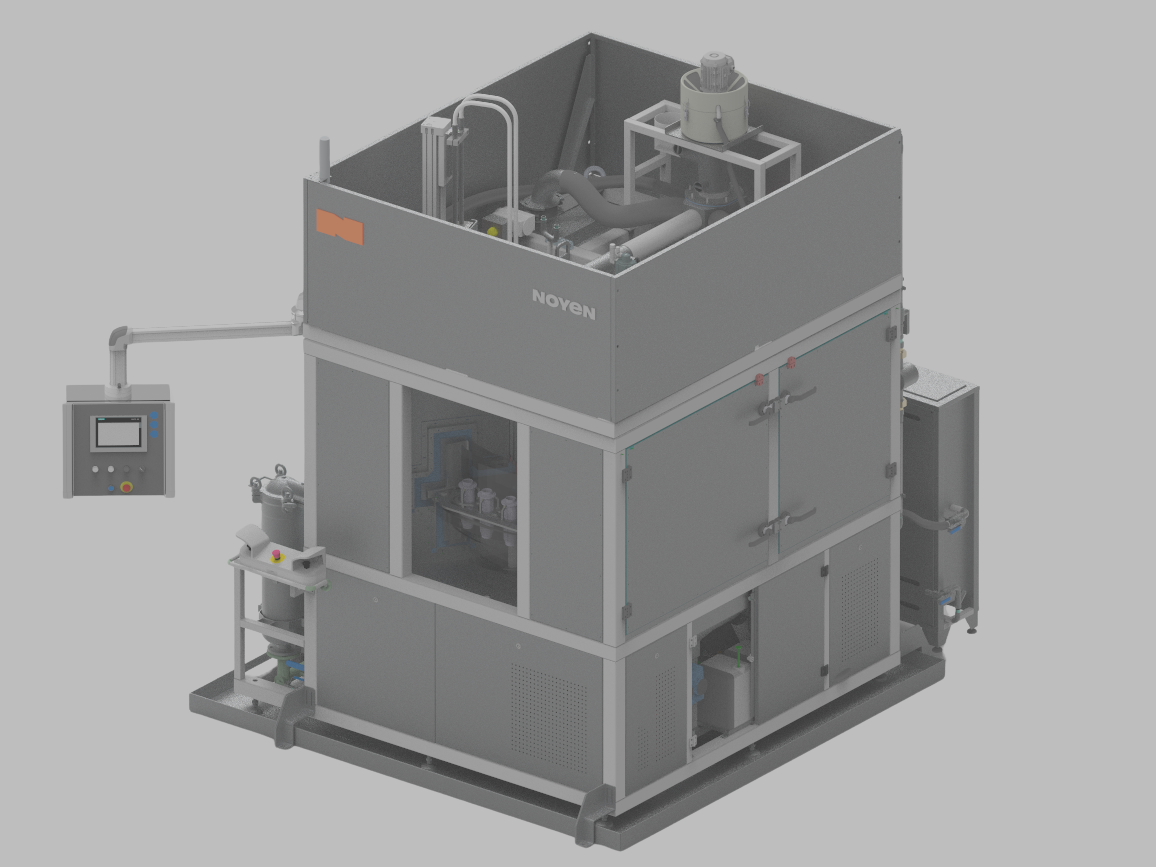

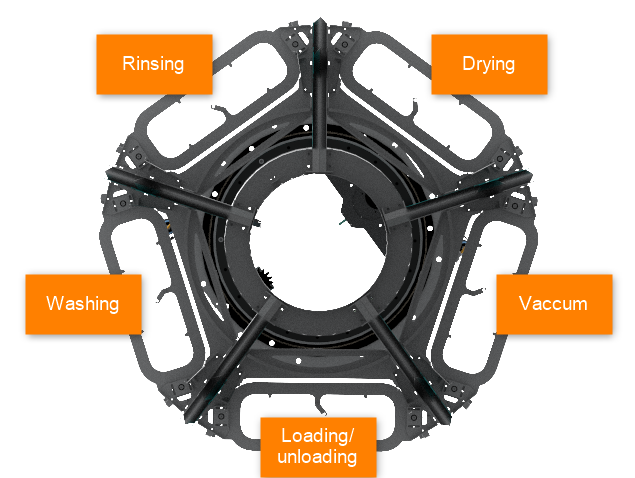

Our experts proposed the NOYEN EXPERT C carousel type indexing rotary table cleaning machine, tailored to the customer’s requirements. The 5 process sections include spray washing, spray rinsing, hot air drying and vacuum drying. Between the process sections, the machine also features neutral and blow-off sections to reduce mixing and cross-contamination of the bath. The last rinse bath uses a product that ensures the stability of corrosion protection.

The design of the carousel-type machine made it possible to meet the customer’s requirement for limited space on the shop floor, while maintaining optimum service and maintenance access to all the essential parts of the machine.

Additional movable nozzles were used for washing parts with openings (gundrilled holes). Parts with through openings were cleaned with movable lances inserted into the part, resulting in a much more efficient and repeatable process than with other standard solutions. To complete the process, vacuum drying was used by enclosing the parts in a sealed enclosure, where residual moisture was extracted and the temperature of the part was further reduced.

What has the client gained by working with NOYEN?

- Meeting the cleanliness standards required by the OEM customer for all parts,

- Compact machine, prepared for manual and automatic loading as a standard,

- Cycle time 30s / part,

- Machine with interchangeable sockets / tooling, which allows the machine to be reprogrammed quickly, or to adapt the machine to future projects.

Nothing is impossible

It will be much easier if you tell us what is the matter. Save some time and sign up for a free consultation. Our expert will advise you free of charge.