More power.

More efficiency.

Advantages

Effective cleaning – provides high quality cleaning of steel, aluminium, copper, brass, galvanised and stainless steel components.

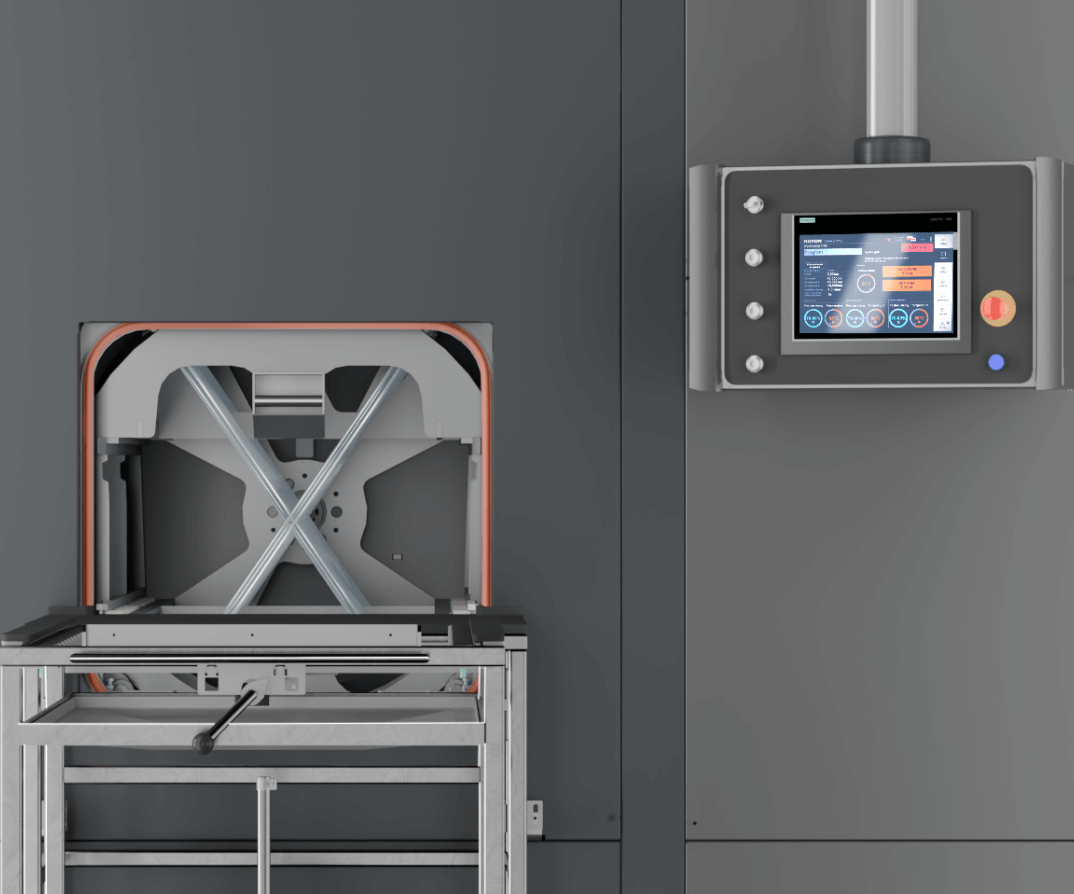

Easier process monitoring – colour lamp in chamber allows remote monitoring of the current phase of the cleaning process, which improves operating convenience and increases monitoring efficiency.

Safety and cleanliness – an oil separator inside the unit allows for efficient oil separation, ensuring long-term cleanliness in the system.

Long-term performance – the filter wear monitoring function allows the condition of the filters to be monitored, which minimises the risk of failure and ensures continuous machine operation.

Ergonomic controls – a customisable HMI panel on the arm provides convenient access to settings and full control of the cleaning process.

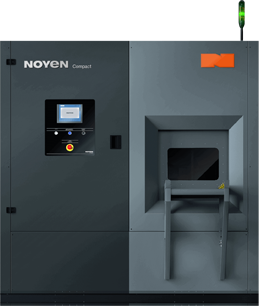

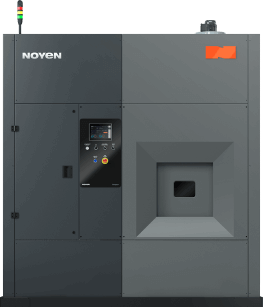

Meet

Compact 600

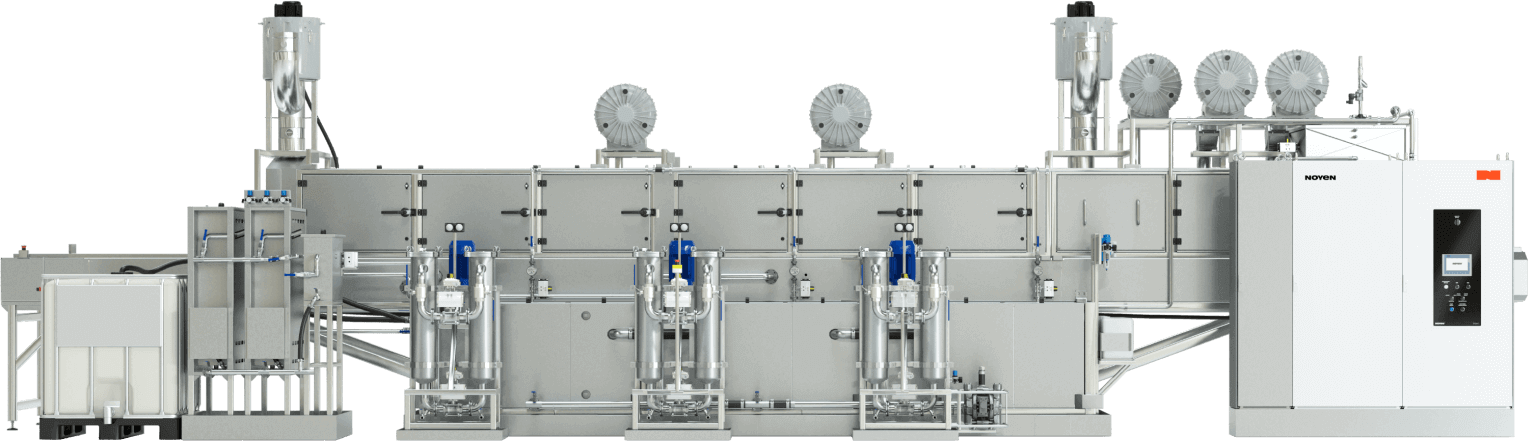

- Vacuum drying system

- Self-sufficient vapor separation system

- Intuitive interface

- Load capacity up to 200 kg

- 5 bar spray pressure

- Drying temperature up to 120°C

- Integration capability with automatic loading system

- Ultrasonic system power up to 8 kW

- More precise rinsing thanks to the additional tank

Compact 600 cleans:

- shafts

- housings

- bearings

- gears

- steel and aluminum castings

- sleeves

- rings

- flanges

- rods

- bolts, screws

Industries

- Automotive

- Aerospace

- Regeneration

- Tool washing

- CNC machining

- Fabrication of small metal components

- Fabrication plants

- Tool plants

- Foundries

- Grinding plants

Efficiency. Technology.

Uncompromising precision.

The Compact 600 adjust to your needs, ensuring reliability and maximum efficiency at every stage of the component cleaning process. It combines advanced technology with convenience of use. With its intuitive interface, colour lamp in chamber, automatic safe chamber door and calendar function, it provides ease of use and full control over the process. The solution that grows with your production.

Technical data

| External size [lenght x width x height] | 3590 x 4160 x 2950 mm |

| Loading height | 1040 mm |

| Basket size | 1 basket 940 x 650 x 300 mm or 2 baskets, each size 651 x 469 x 300 mm |

| Payload | up to 200 kg |

| Spraying pressure | 5 bar |

| Tank capacity [liters] | 1500 + 2 x 1000 + 50 |

| Water tanks | 3 |

| Thermal insulation | Armaflex |

| Ultrasound frequency | 8 kW, 25 kHz |

| Vacuum drying system | Option |

| Coalescent oil separator | Standard |

| Automatic water refilling system | Standard |

| Automatic chemical dosing system | Standard |

| Automatic loading system | Option |

Nothing is impossible.

It will be easier if you just tell us everything. Save your time and make use of your free consultation. Our expert will advise you for free.