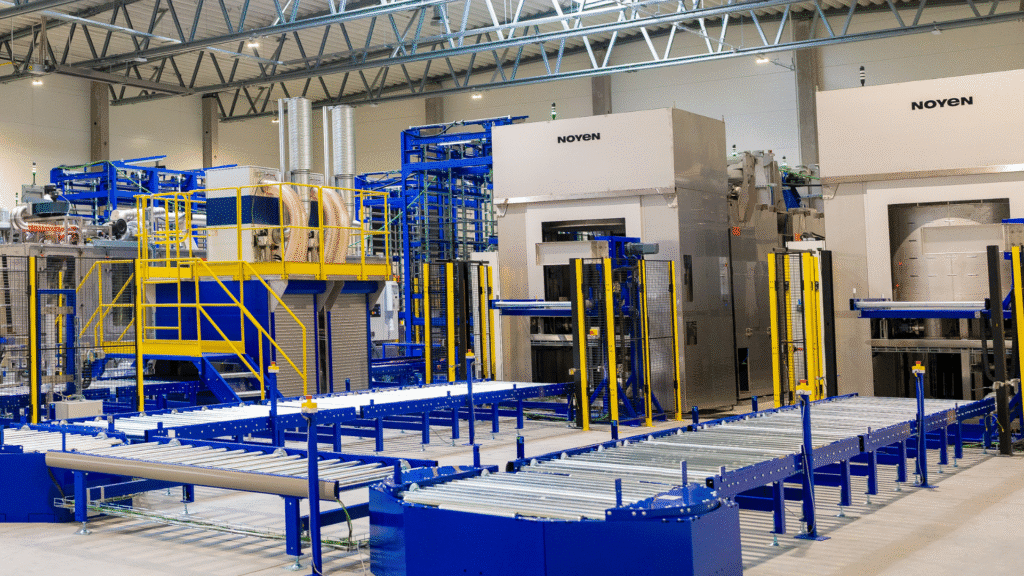

In a modern industrial plant, cleaning is no longer a single stage but an integrated part of the production process that must be fully synchronized with other operations. In these environments, large-scale, fully automated cleaning lines, individually tailored to specific technological needs, offer the most effective solution. At NOYEN, we design cleaning systems as complete technological solutions. Their development requires a deep understanding of each customer’s production process not just the cleaning stage, but how it interacts with the broader manufacturing flow. Large cleaning lines are designed as an integral part of a production system. They account for production takt time, process sequencing, plant footprint, and the level of automation within the facility. Each line is built from the ground up, based on:

- component geometry and materials,

- type of contamination,

- required throughput and cycle time,

- available production space,

- integration with existing robotics and control systems.

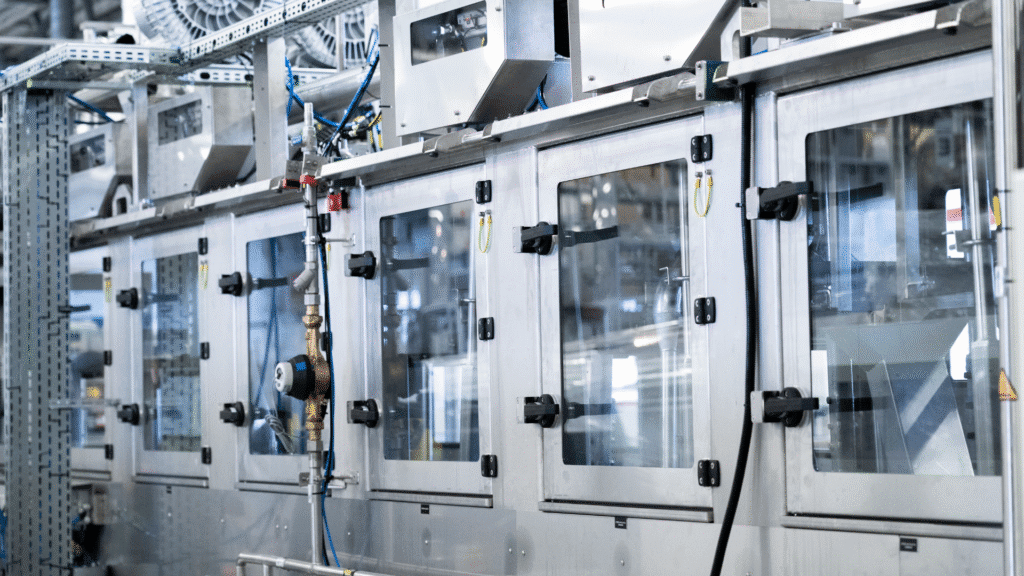

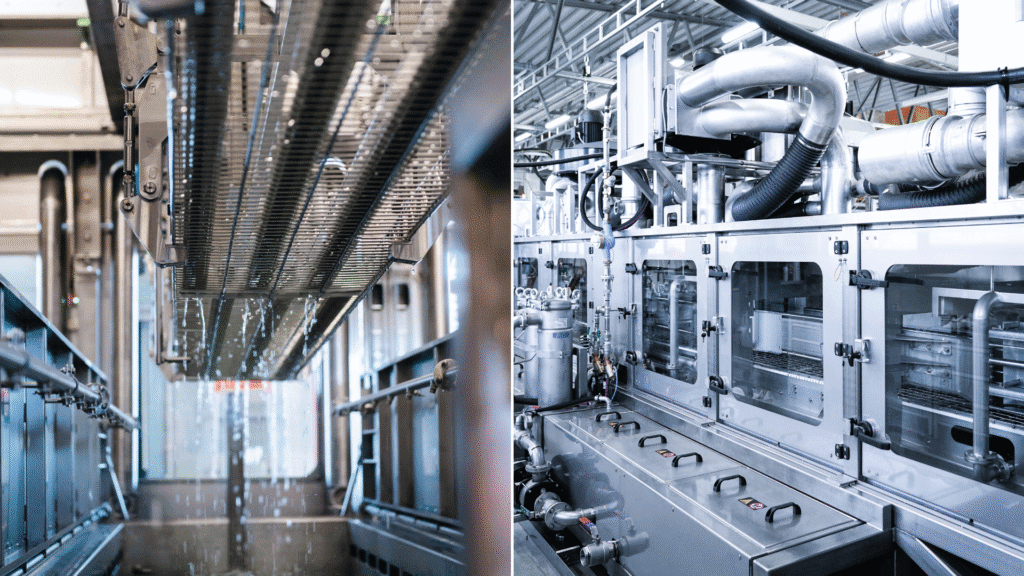

The result is a system that supports, not disrupts production. It simplifies operations, enhances process reliability, and improves safety. Large lines allow the use of different technologies in a single system. We can combine multiple stages in a single sequence, e.g., pre-degreasing, precision washing, rinsing, or vacuum drying – all centrally controlled and fully monitored. Such technological flexibility is key when the line is to handle parts with different requirements or variable production volumes. We design our systems for high-performance industries, where throughput, repeatability, and reliability are critical. These include:

- Foundries (e.g., cleaning of castings before machining or assembly),

- Stamping plants (e.g., washing pressed sheet metal components),

- Forging shops (e.g., removal of scale and oils from forged parts),

- Fastener manufacturers (e.g., precision washing of screws, bolts, nuts),

- Metal processing plants (e.g., for large-scale production of connectors, sleeves, and structural elements),

- Packaging component manufacturers, and others involved in high-volume production of metal parts.

Depending on the application, our systems can clean parts such as:

- threaded fasteners,

- automotive brackets and housings,

- bearing components,

- complex cast or forged elements,

- formed and stamped profiles,

- assembly-ready precision parts.

NOYEN’s large-scale cleaning lines are fully equipped to operate in automated, high-volume environments. Integration with robotic handling systems, conveyors, and manufacturing IT infrastructure ensures consistent operation and full traceability. Advanced vision systems and measurement technologies can be integrated to:

- verify part orientation and presence,

- detect surface contamination,

- monitor process effects in real time,

- and ensure compliance with cleanliness standards.

Each part can also be tracked through the system using barcodes, 2D codes, or RFID -enabling detailed traceability of the production flow. The system identifies each part as it enters and exits the line, recording parameters such as wash cycle, temperature, pressure, and operator input. This allows manufacturers to link quality data to specific parts, batches, or customers. Process control is handled through a user-friendly HMI interface. Parameters can be tracked per part, per order, or per batch, providing meaningful data for quality and maintenance teams and enabling full process validation. While achieving technical cleanliness is the primary objective, the overall efficiency of the system is just as important in large-scale lines. When properly designed, a cleaning line can:

- shorten cycle times and increase throughput,

- reduce water, energy, and chemical usage,

- minimize human error,

- enable continuous and unattended operation.

For many plants, this transforms the cleaning line from a supporting machine into a strategic element of the production process – one that directly contributes to yield, consistency, and operational control. Building a large cleaning line is always a complex project. It requires not only technical knowledge but also understanding of real-world production conditions, regulatory standards, and quality expectations. At NOYEN, we take responsibility for the entire process: from preliminary analysis, laboratory testing, and technology selection, through design, to commissioning, training, and documentation. We deliver systems with full service support and the possibility of further development.

In summary, large cleaning lines are not just a response to rising cleanliness standards, they are a tool for streamlining production, improving efficiency, and reducing risk. They help manufacturers operate faster, more confidently, and with greater process control. At NOYEN, we build systems that do more than clean. They strengthen production – technically, operationally, and strategically.

NOYEN – industrial chemicals and machines manufacturer, which comprehensively meets the needs in the field of industrial cleaning, machine service, automation, laboratory tests and chemistry. Check out our wide range of cleaning devices and find out how NOYEN can support your business – contact our specialists.

Nothing is impossible

It will be much easier if you tell us what is the matter. Save some time and sign up for a free consultation. Our expert will advise you free of charge.