Industrial machine design – what does it involve?

Industrial machine design is a complex process that requires knowledge and experience. We start the process of designing a device by understanding the needs, visions and ideas of our customers. Using the latest technologies and methods of cleaning machines’ design, we create standard as well as customized solutions tailored to the specific needs of our customers. The result of this work is innovative industrial cleaning machine that provide process efficiency, designed with ergonomics in mind.

An important aspect of the process of industrial machine design is to know the specifics of the industry represented by our customers and the specifics of the company itself. Our goal is to respond to specific needs and requirements, so we work closely with the recipients of our solutions at every stage of the process.

Industrial cleaning machine design – how does it proceed?

Designing cleaning machines is an integral part of the process of creating modern equipment that supports the automotive, remanufacturing, medical, electronics, aerospace or metalworking industries. This complex process requires careful planning, creativity and in-depth technical knowledge. From concept to completion, each design stage is critical to the final result.

Defining requirements and specifications

The first step in the design process for cleaning machines is to carefully define the requirements and specifications. In this phase, engineers together with the customer analyze the needs, goals and expectations of the designed device. It is important to consider all relevant factors, such as technical parameters, performance, safety, or compliance with industry standards and regulations.

Concept and preliminary design

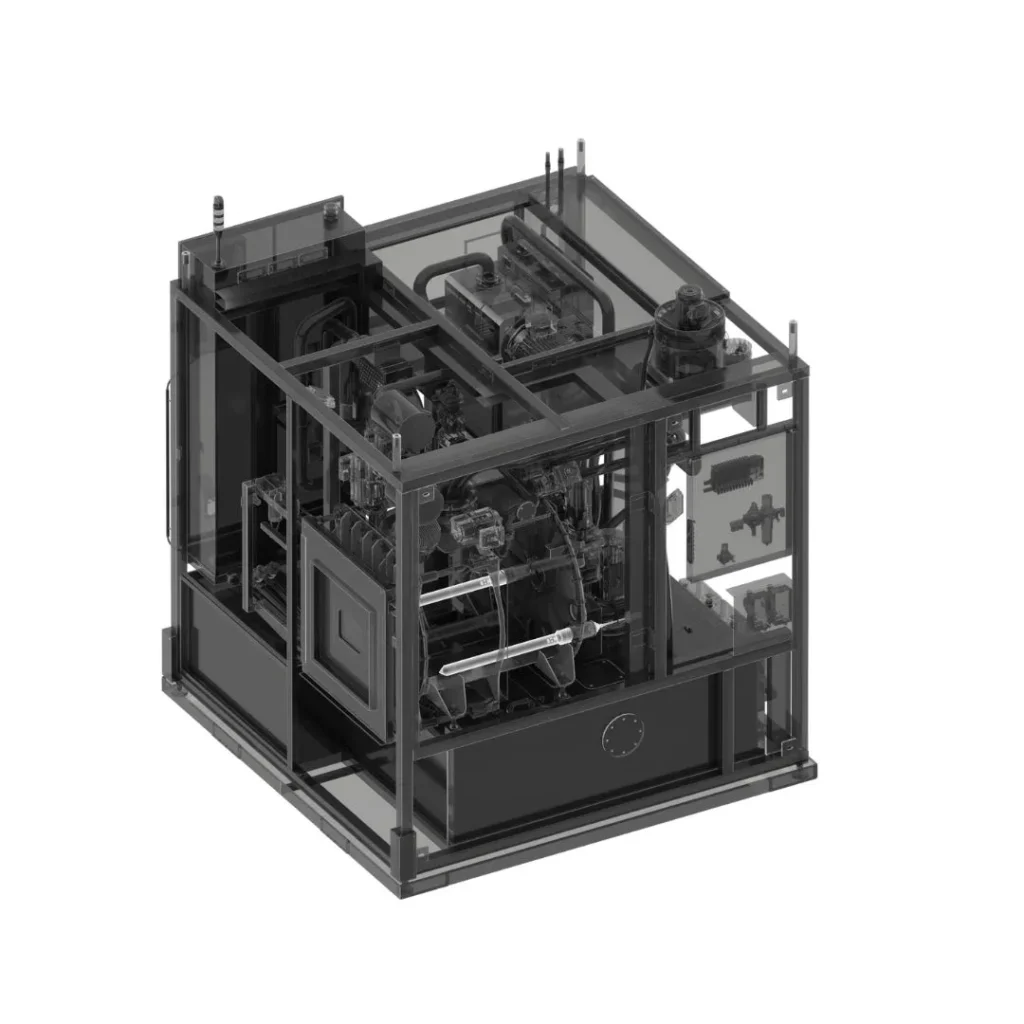

Based on the collected requirements, engineers proceed to create concept and preliminary designs. A variety of tools are used in this phase, such as CAD (Computer-Aided Design) software, which allows the creation of precise 3D models. Designers look for optimal solutions to meet the technical and functional challenges set before them.

Analysis and optimization

The next step is to analyze and optimize the created designs. Engineers perform a detailed evaluation of each machine component, identifying potential problems and looking for ways to solve them.

Prototyping and testing

The design phase is followed by prototyping and testing of the created solutions. The prototype allows to verify the correctness of the design assumptions and identify any errors or imperfections. Testing takes place under various conditions, often in near-real conditions, to ascertain the reliability, performance and safety of the cleaning machine.

Production and implementation

The final stage of the project is the production and implementation of the machine at the customer’s site. After prototype testing is completed and any corrections are made, the machines are ready. Deployment of the machine also requires adequate preparation in terms of risk assessment, development of operating instructions, personnel training and service support.

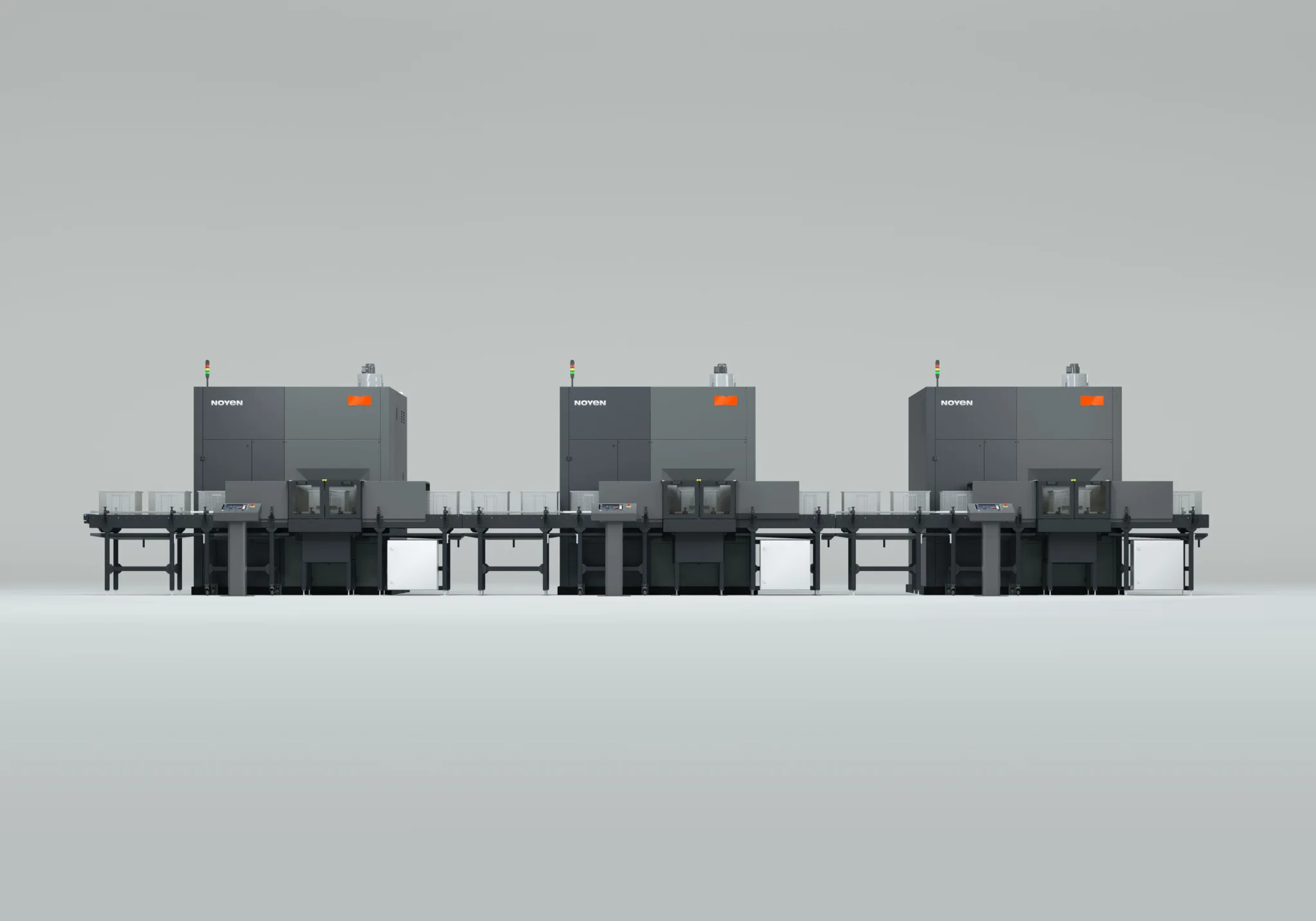

Designing cleaning line with NOYEN

We start the industrial machine design process by gathering all the information about customers’ needs and expectations. We establish the technical assumptions of the project, cleanliness standards, photos and drawings of the details, factory standards and installation site. At this stage we also clarify ambiguities arising from the specifications. Once the entire scope of the project has been established, the process of working on the concept of the cleaning machine in the concept development department begins, often in an interdisciplinary team together with the design department and the chemistry department. At this stage, washing tests with the selection of technology indicating the best method to safely remove contaminants are also often performed. The layout of the device or cleaning line in 2D is created first in ZW CAD and the spatial concept of the device in Solid Edge (3D).

The ability to work on virtual 3D modeling is a great convenience not only during the design of large lines and machines integrated with equipment already present in the customer’s production plant, but also during the development of electrical and software design. An additional benefit is the ability to consult solutions with the customer even before the machine is manufactured, which allows for a significant reduction in potential validation costs on a manufactured machine and shorter delivery times. Modifications made later in the machine’s life cycle are faster, easier and more efficient. NOYEN engineers can introduce them using a 3D model. The application of changes at the customer’s site is more efficient in this case, thanks to the greater knowledge of the assembly department’s employees about where and how to make modifications.

After determining the initial solution and concept of the device, we present a non-committal commercial offer with a budget. After acceptance, the concept is finalized in cooperation with the customer and the order is accepted.

The cleaning machine concept accepted by the customer is transferred to the construction department, where the 3D model of the cleaning machine and the technical description (manufacturing and assembly drawings, calculations and technological assumptions) are developed. A fixed point in the construction process are meetings with the customer. They are used to check progress and answer questions. The design phase ends with a meeting during which the finished machine model is presented to the customer, along with the finest details. The entire process is overseen by a Project Manager, whose job is to plan, supervise and execute the project, ensuring its successful and timely completion. The final stage of the process is the production of the device and implementation of the solution at the customer’s site.

We are specialists in industrial cleaning, cleaning process automation or industrial chemicals. NOYEN experts provide comprehensive industrial cleaning solutions every day, responding to the needs of customers in various industries. By selecting the right technologies and equipment, we elevate cleaning processes to the highest level of quality, improving the overall efficiency and quality of the production process. Our cleaning machines’ designs are tailored to the specific needs of different sectors and take into account:

- the specific needs of the customer,

- the challenges of the ongoing production process and its optimization,

- achieving the required cleanliness standards,

- operator safety.

To take advantage of our offer, please contact us by phone: +48 81 745 05 98 or by e-mail: . We also encourage you to use our contact form.

Nothing is impossible

It will be much easier if you tell us what is the matter. Save some time and sign up for a free consultation. Our expert will advise you free of charge.